What challenges do we solve for rail transport and agriculture Will the next case study explore electric trucks? The new Case Studies section on the Promens Zlín website offers concrete examples of collaborations that highlight our technologies and working methods.

Our projects often arise within very specific contexts—responding to technical challenges, the need for greater efficiency, or the transition to new materials. The new Case Studies section demonstrates how Promens Zlín approaches every project individually, emphasizing functional solutions and long-term reliability.

Tailored Solutions for Mobility and Agriculture

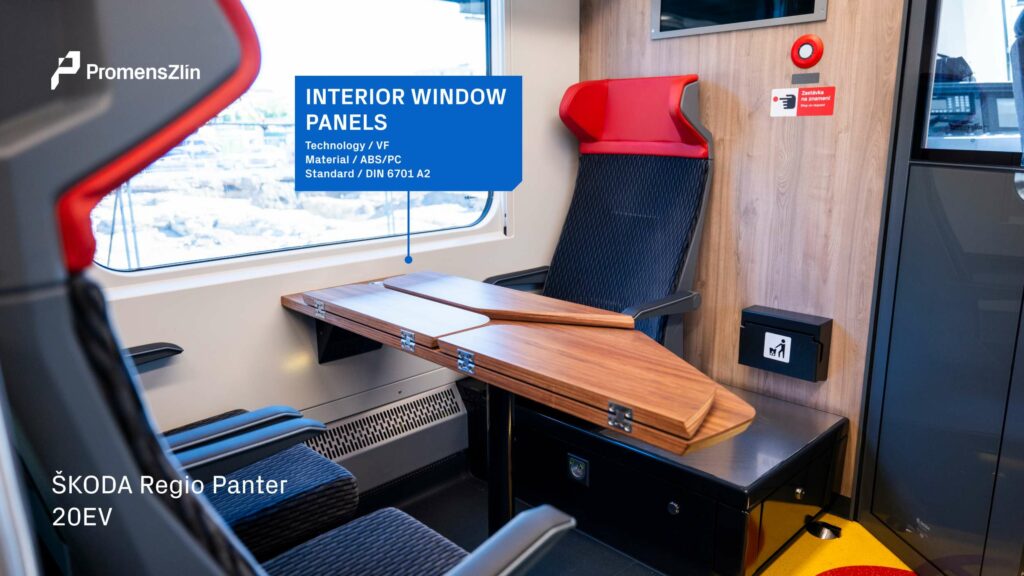

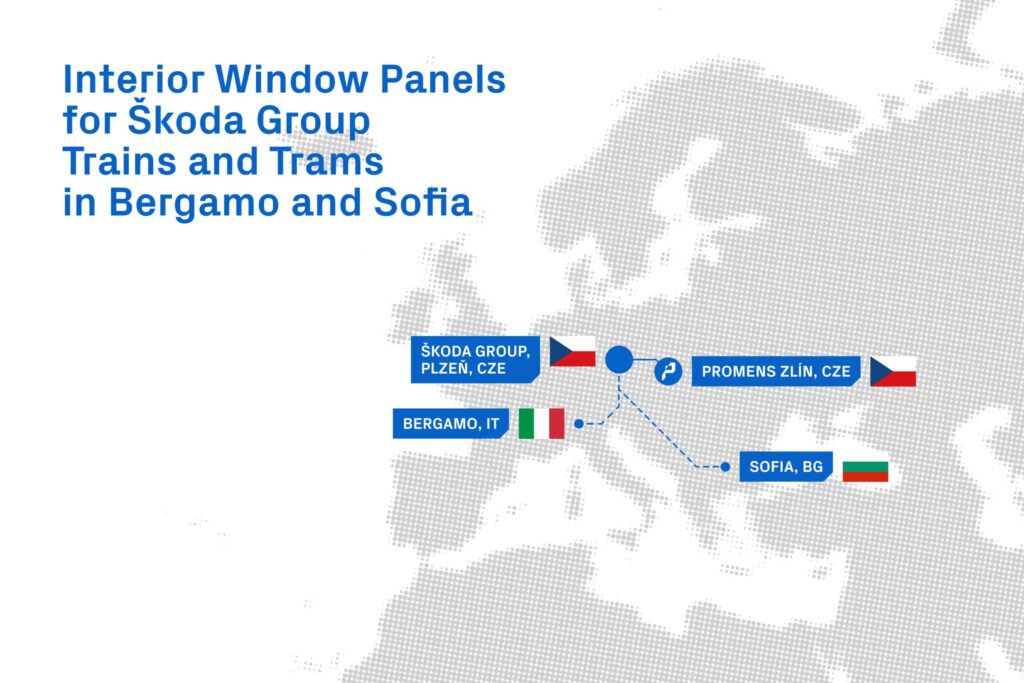

Our case studies present specific applications for trains, trams, and tractors. They illustrate not only the individual parts but also the entire process—from development and selection of manufacturing technology, through testing, to logistics.

Among the featured projects are thermoplastic panels for electric units by ŠKODA Group and a specialized painting system for CNHi tractor fenders.

These solutions help our customers gain a competitive edge.

Meeting CNHi’s technical painting standards was essential—requiring precise matching of shade, gloss, texture, and coating parameters. On top of this, additional quality criteria included abrasion resistance, high UV stability, paint flexibility matched to the substrate, and resistance to cracking under sharp impacts.

Solutions That Stand Up in Practice

Every product that leaves our facility is designed with its specific application in mind. Whether the focus is on enhanced durability for off-road conditions, the aesthetic cleanliness of vehicle interiors, or the efficient logistics of high-volume parts, we always strive to find a balance between technical solutions and costs that are tailored to our customers’ requirements.

We select technology combinations with a strong emphasis on achieving the desired cost/performance ratio.

“Case studies are a great way to show how Promens Zlín connects development with production.

With support from our in-house R&D team, we optimize manufacturing to achieve the best cost/performance ratio while delivering real added value for every application.”

Roman Bořuta, Sales Manager Promens Zlín

Upcoming Case Study: Robotic Bonding for the Truck Segment

We are confident that these case studies will be both inspirational and practical examples of what Promens Zlín can achieve. Over time, we will expand this section to include projects from various industrial sectors, and we would be delighted to feature your project among them in the future.

Our next case study will focus on the development and production of robotic bonding technology for electric trucks. It will showcase how automation enables us to achieve maximum precision, consistency, and joint quality for large plastic components used in trucks.

Explore Our Case Studies

Curious how plastic part development and production happen in real-world applications? Visit our new Case Studies section and explore examples of collaborations that are transforming mobility and machinery.