Examples of elements most often mounted in assemblies are lights, curtains, reinforcements, anti-noise elements, washers, grills, metal reinforcements, fixing elements, including the actual connection of individual plastic parts into assemblies (e.g. bonnets).

INTEGRATED SUPPLIES OF ASSEMBLY UNITS

Due to the integrated supplies requirement, most large exterior plastic parts in Promens Zlín undergo assembly operations.

We offer assembly, including the connection of individual plastic parts into assemblies (e.g. hoods).

FREQUENTLY ASSEMBLED PARTS INTO ASSEMBLIES

- lights;

- suspensions;

- reinforcements, fixing elements and metal reinforcements;

- anti-noise elements;

- washers;

- grills.

Gluing

Gluing as such is one of the most demanding operations – both in the development phase and in ensuring full reproducibility during the production process. The system used must be able to meet the adhesion and cohesion requirements.

At the same time, it must accept possible variance in shape connections during production and have constant properties over time. Optimization of the dynamic stress of the part is obvious.

We use a number of systems for gluing, such as polyurethane sealants, MS polymers, cyanoacrylate adhesives and others.

The gluing operation is one of the most demanding in terms of compliance with technical requirements during the production process. In Promens Zlín, it is one of our specially monitored operations, one which is subject to a strict inspection regime.

Ultrasonic welding

Ultrasonic devices are currently the most widely used for welding operations, ensuring minimal defects on the front side of the product.

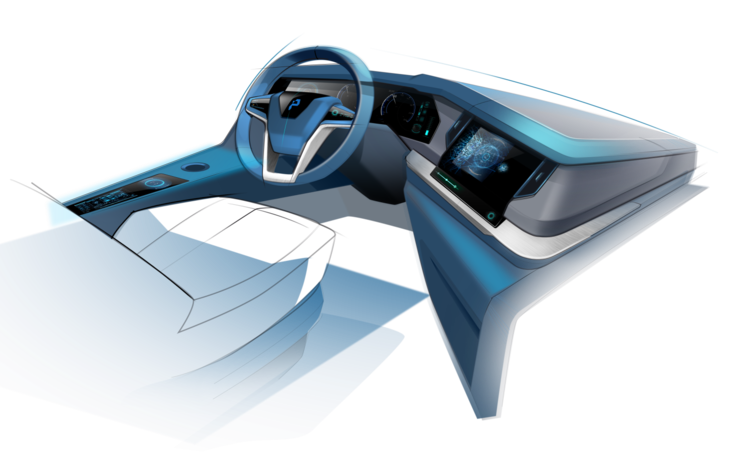

Tailor-made applications

We develop, manufacture and supply parts for major manufacturers throughout Europe.

At Promens Zlín, we choose a combination of technologies according to efficiency, seriality, material and production price according to the required cost / performance ratio.

As a standard, we also address the requirements of Advanced Logistics. Our advantage is that after R&D and production we can supply parts assembled into Just in Time assembly units. We are a partner for manufacturers and for Just in Sequence deliveries.

With these solutions, we help customers be successful in the market.

We work for the best

Photos from production

RESEARCH AND DEVELOPMENT | PRODUCTION | PAINTING | ASSEMBLEMENT | JUST IN TIME & JUST IN SEQUENCE

We are experienced Tier 1 development suppliers.

Together, we will make your project succeed.

Call Us

+420 577 051 154

Mail Us

zlin.sales@promenszlin.com