Summer break at Promens Zlín

Please note that we will be taking a company-wide holiday from August 4 to August 15. During this time, we’ll recharge our batteries so that we can return full of

We are a reliable partner for our customers in the supply of plastic parts and assembly units, designed for the most demanding applications. We help them meet their goals in the areas of development, supply, quality and safety. Together, we have developed a successful, long-term market presence.

We operate on the global market as a development and systems supplier. We value the commitment and loyalty of our staff and invest in their development, whilst ensuring a safe working environment.

3D

Implementation & Simulation Analysis

Assembly, gluing and welding

Just-in-Time (JIT) & Just-in-Sequence (JIS)

The result of our work is the movement of machines and vehicles, which make work easier and shorten distances.

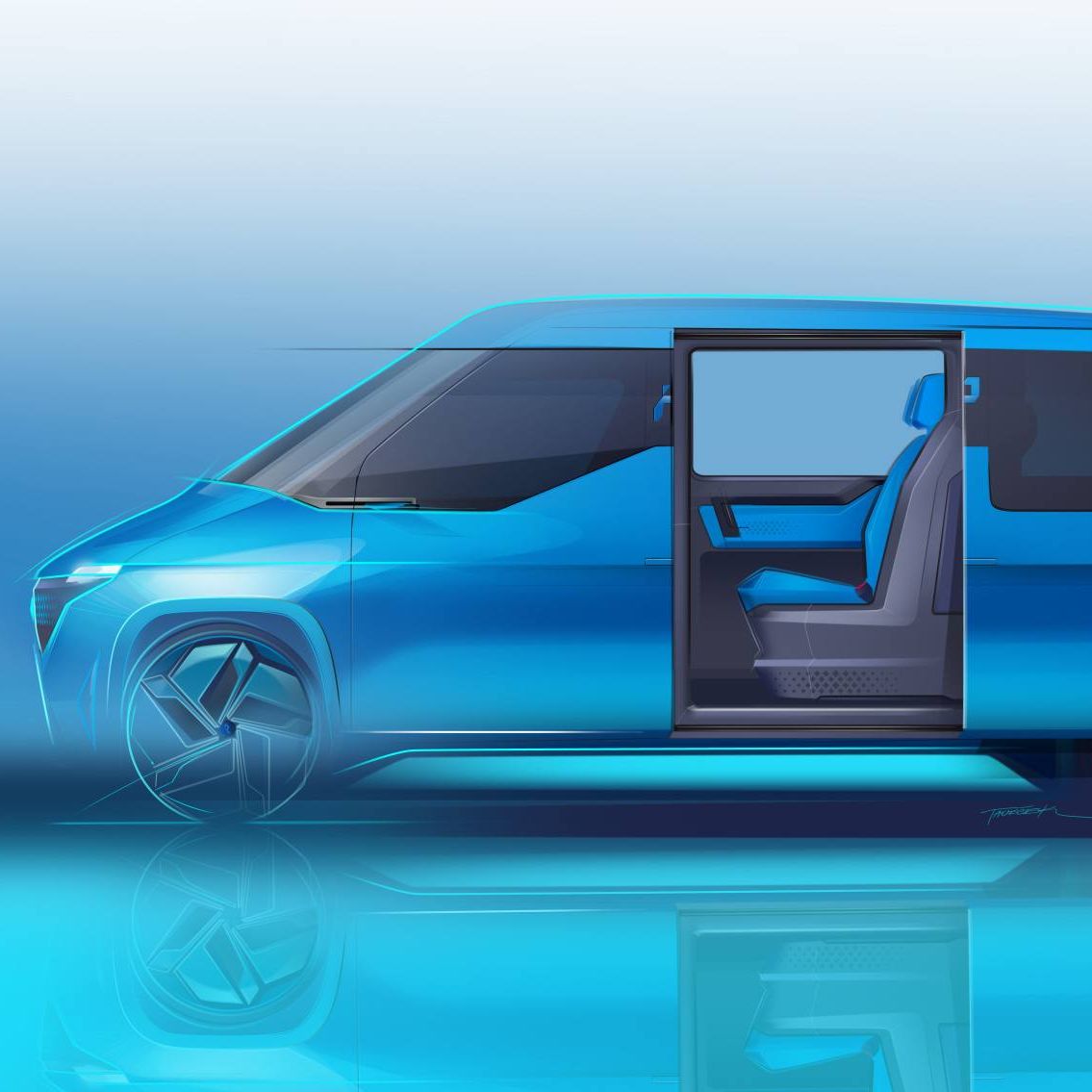

Our company is one of the most sought-after manufacturers in the field of buses.

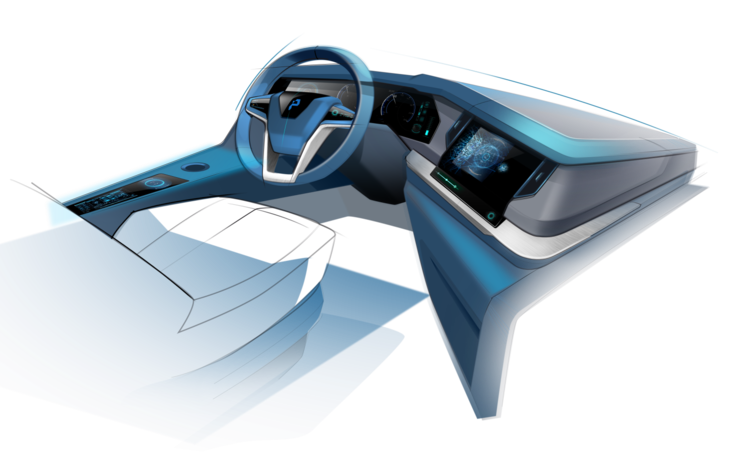

We have the most comprehensive range of plastics technologies – DCPD-RIM, vacuum forming, rotary casting, injection moulding, PU-RIM and pultrusion. From a single part to a complete solution of the driver’s compartment.

Speed and reduced aerodynamic drag and noise, as well as passenger comfort.

Our development and production of components for modern train and tram sets shorten distances and enhance the appeal of public rail transport.

Loaders, dumpers, vibratory rollers, excavators and other machinery and equipment. We are well aware of the demands in this segment.

Mechanical properties, temperature resistance, visual demands, serial production, variability and other challenges. We have extensive experience in this field, whether it concerns the production of individual parts or complex assemblies and functional units.

Acceleration, lower consumption, better ergonomics. We help customers to increase the efficiency of each truck.

Tractors, combine harvesters, mini tractors and other machinery and equipment.

RIM technology and vacuum forming are suitable solutions for many applications such as complete engine hoods, fenders, roofs, interior parts and more.

We develop and manufacture parts and assemblies for medical, aesthetic, laboratory, and diagnostic devices.

Discover stories of successful collaborations with partners from the automotive, medical, and other industrial sectors. Our case studies showcase how we use top-quality plastic parts and enclosures to deliver effective solutions for diverse technical challenges.

Through close partnerships with clients, we provide reliable, customized solutions that meet the highest standards of quality and performance.

Explore how we’ve helped our partners achieve success – and see what we can do for you.

Tomáš Baťa said “He who stands still for a while, falls behind.” We don´t.

Movement and dynamics are the result of our work – with regards to machines and humans alike.

Please note that we will be taking a company-wide holiday from August 4 to August 15. During this time, we’ll recharge our batteries so that we can return full of

What challenges do we solve for rail transport and agriculture Will the next case study explore electric trucks? The new Case Studies section on the Promens Zlín website offers concrete

JEC Paris serves as a single venue where technological innovation, strategic partnerships, and key topics shaping the future of transportation and industrial manufacturing converge, with a focus on weight savings,