In the beginning there was a development team, which over the past thirty years has grown into a direct supplier of a number of important companies in the Czech Republic and abroad. Its customers are in the automotive industry, but it is also expanding its portfolio to the non- automotive segment.

Promens Zlín a.s. is primarily a development and system supplier of interior and exterior large-scale plastic parts for buses, but also fairings for construction machinery or agricultural machinery. Despite the outages in the supplier-customer chain, the Company is growing and investing, as business manager Roman Bořuta states in the interview.

You supply the leaders of the automotive industry. How are you currently doing? Do you have enough orders?

There are enough orders. However, input prices and major disruptions in the supplier- customer chain are still a problem. Customers are still halting production due to shortages of various components and we are facing constant changes in Forecast. A strong Czech crown was recently added to the mix, which does not work in our favour as an exporter.

“But we can answer the question of how we are doing: Okay, we got used to it.”

Roman Bořuta, Sales Manager

What challenges have you got to deal with?

As I mentioned earlier, the market is still not where it was before 2019. There are still outages. But for me it’s about fifty-fifty. Part of it is better, part of it we have learnt to live with.

The biggest challenge is the ever-changing customer orders, as many of them change production based on what they have the components for, and these changes are prescribed throughout the chain.

On what projects, and for which car companies, are you currently working?

With the new SMC technology we made a big push into the truck and transportation segment. It is bearing fruit and we are working on interesting projects for both trucks (Volvo Truck, Iveco Truck) and trains (Škoda Transportation).

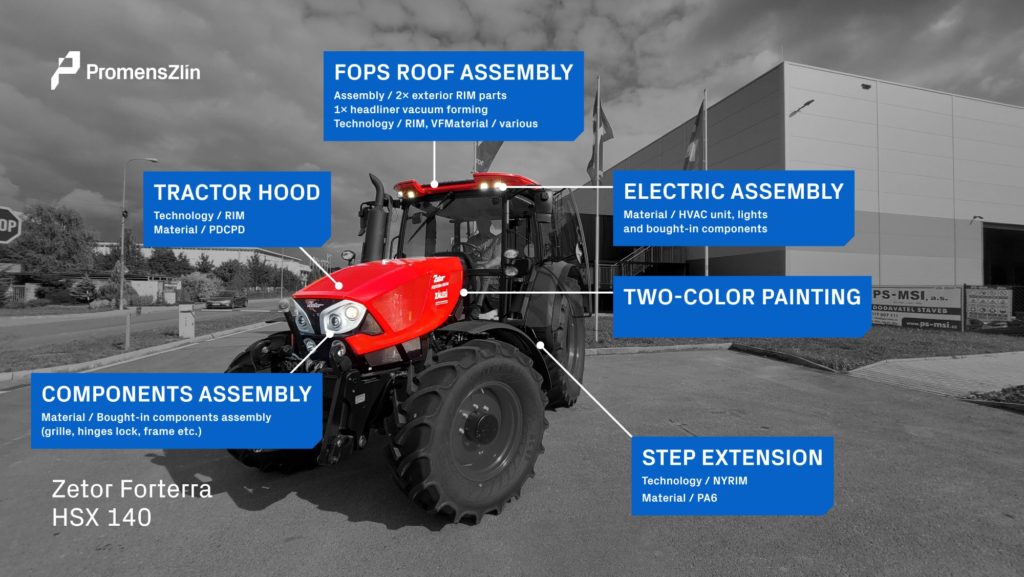

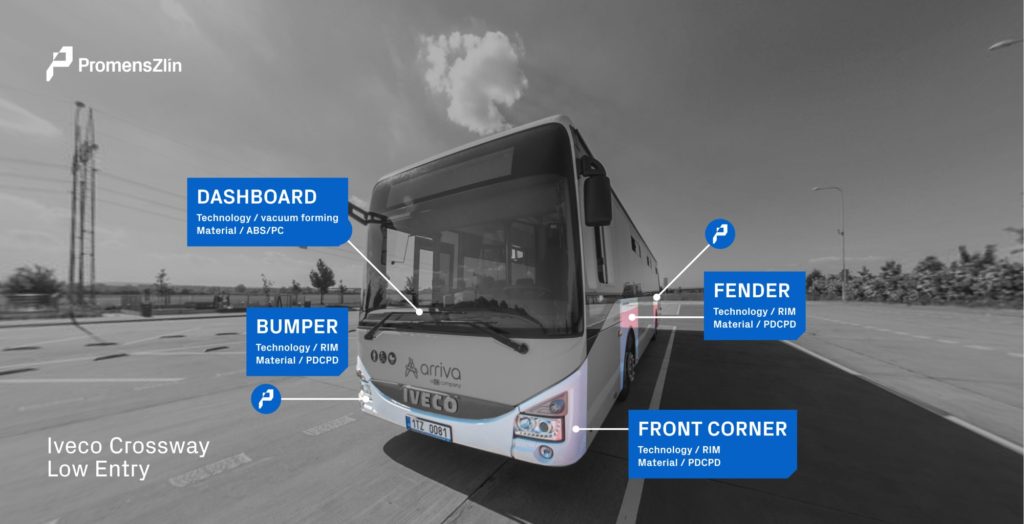

We also continue to work on new projects for our customers, such as Iveco, Volvo CE and Zetor.

Then there’s another sector where a big boom is happening and where there is a lot of demand, and that’s sustainable energy. Due to volume increases wind farms, battery storage, air conditioning and heat pumps are looking for new materials and more serial processes than laminate. Here we cooperate with companies such as Northvolt, Samsung, Eberspracher and Trane Technologies.

You are the only European manufacturer with RIM, SMC and vacuum pressing technologies under one roof. What benefits does this pose for your customers?

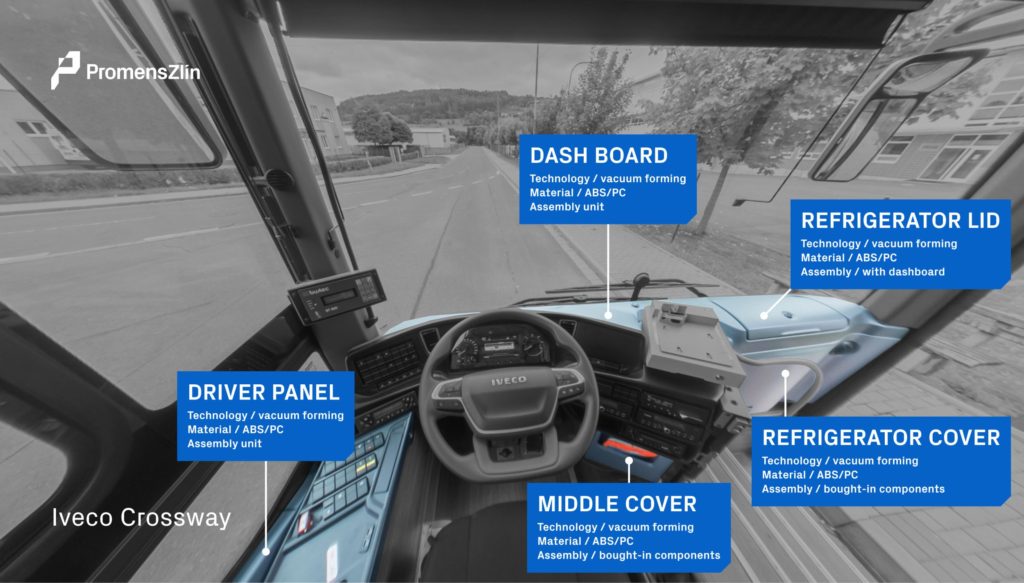

As far as we know, yes, we are still the only European manufacturer with these technologies. We have competitors that combine RIM with, for example, classic injection, but I don’t know of a company that has RIM, SMC and vacuum together. These technologies are for large parts in small and medium series, with RIM and SMC mostly used for exterior parts (fenders, bumpers, hoods, roofs), while vacuum forming is more suitable for interiors (dashboards, trim, etc.).

“So the benefit for our customers is simple. With us they can deal with both exterior and interior parts, and if necessary we can combine these technologies together.”

Roman Bořuta, Sales Manager

You are famous for being able to combine different production technologies. Can you give a specific example of a project that you are proud of?

It is an Iveco Bus dashboard that combines vacuum formed parts and PUR parts to optimise costs. Or a roof for Zetor tractors.

This is a complete tractor roof assembly, but the supporting parts are the RIM roof and the vacuum formed soffit. Third in line would be Volvo Construction hoods, which also combine RIM parts on the outside and vacuum formed parts on the inside.

What projects, innovations or machines will you invest in this year? What is your priority in terms of investment?

Now we are in a state where we are invested. At the end of 2022 we completed the construction of the new RIM hall with an area of 14,000 square metres, where we also have our own paint shop.

New production area Zlín2.

Robotic and manual painting lines in Zlín2.

We have also invested in two SMC presses. In terms of machines we made the biggest investment in an SMC press with a tonnage of 3,000 tonnes and part dimensions of 3.6 x 2.5 metres.

So, this year and next we are expecting a rather standard addition of machines according to the capacity outlook – a small VF press or CNC.

But there is one very special investment – we started building our branch Promens Düzce in Turkey, where we are locating thanks to Iveco. Considering the potential of the Turkish market and the difficulty of the project, this will definitely be our priority for the coming years.

You work as a development and system supplier. What are the main trends in your industry? What do you do in development?

One of the trends we’re seeing with inflation is that all customers are looking for savings and new materials and technologies to make their products cheaper. I think this will be the trend for at least the next two years and I am not surprised because our customers need to mitigate the impact of inflation as much as possible.

“I would probably highlight the development with the customer Volvo CE, namely single-layer painting without primer or the development of VF train linings with the customer Škoda Transportation. We have achieved a cheaper solution while maintaining the same quality.”

Roman Bořuta, Sales Manager

In addition to the already mentioned, the development of heat exchangers with microfibres pressed into the RIM matrix is still ongoing – but there is still a long way to mass production.

How many people currently work for you? What environment are you creating for them? What do you emphasise within the team?

We currently have around 380 people. At our Company, we’ve been building a company culture based on Franklin Covey’s Seven Habits of Highly Effective People for some time. We also cooperate with the Tomáš Bata Institute, which shapes our environment – we want to be transparent, fair, but demanding at the same time. When the performance and results are above standard, so is the reward. In our team emphasis is placed on the best idea and the best solution to come first, not one’s strong personality.

What positions do you most often fill and what benefits do employees find with you?

In recent years these have mainly been blue-collar positions. As we grew, thanks to the completion of a new paint shop and outsourcing all home painting, we grew from approx. 50 people in the paint shop in 2019 to a team of over 100 people. Otherwise, of course, all possible positions are filled, according to growth – purchase, R&D, sales, production, but there it’s about individuals. Benefits, if I leave out the standard ones offered by a recruiter at an interview, such as five weeks vacation or a pension contribution, then I would say there are three more. First of all, we are a ‘standalone’ Czech company with a complete structure from marketing, sales, development, production to purchasing. Secondly, we have the opportunity to grow – anyone who really wants to can grow very high here. And third, we have a company culture of open communication – everyone can have their say. Besides, as it turns out now, we can deal with the times. Not only us, but also other companies in the Czech Republic. Whether it was Covid, now war, inflation, exchange rate risk and other events. Through it all, we continue to live and grow.